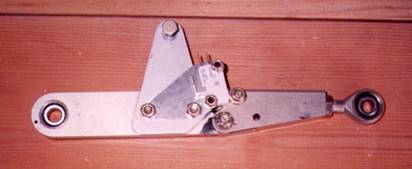

This little article was published in the Lancair Network News several years ago. It describes the installation of landing

micro switches on the over center links rather than (or in addition to) mounted

to main gear bracket.

3 Green and Landing Gear Micro

Switches

When

flying aircraft with retractable gear, one of the greatest moments of

anticipation

occurs while you wait for those three little green lights to

illuminate

upon selecting gear down. I don't know what the GA rate of gear

system

failure is, but I have had five gear incidents in my 300 hours of retract time: One was

in a certified plane, four in experimentals, three of

which were in my 360. Only in the certified plane was there a

true system failure, the others where all indication

problems. The three incidents in my 360 where traced to the

method by which the down and locked position is sensed

by the micro switch on the main gear. To determine if

the links

have actually gone over center, one needs to detect the position of

the two

links relative to each other. On the 360, the micro switches monitor

this only

indirectly. They are positioned such that they measure the relative

position

of the upper over center links to the aircraft structure. Assuming the

relative

position of this link to the fuselage is always the same on all axes

when the

gear is down and locked, this approach would be quite adequate and

simple to

install. In our case, a roll pin in the link depresses the lever on

the micro

switch. The problem with this set-up lies in the fact that both ends

are

supported by bearings that allow rotation about a line drawn between the

bearings.

Rotation about this line, when the gear is down, will raise and lower

the

position of the roll pin relative to the micro switch. A large washer on

the

mounting bolt of the upper over center link is used to prevent this rotation

or at

least most of it. If you adjust your micro switches to trip only when the

links are

truly over center, not much movement is required to indicate an unsafe

condition.

This little bit of movement can occur by forcing the linkage to

rotate as

described above. The quickest remedy is to adjust the switches such

that they

activate a little earlier, possibly just before the links go over

center. By

doing this, any amount of pushing or pulling on the linkage will not

be able to

give a false unsafe condition. The draw back is that you get green

lights

while the gear is not yet locked. From a practical standpoint, if the

gear has

gone down 95% of the way to trip the switch a little early, chances are

it will

travel the remaining 5% and actually lock.

For some time I toyed with the idea of mounting the

switches in such a way that they could only activate

when the links were truly over center, completely

independent

of the above effects. I like solutions that are inexpensive, simple

to build,

and reversible. That way if it doesn't work I haven't lost a lot of

time or

money and I can have my old parts back. The enclosed picture shows the

set-up I

am now testing. It only requires an aluminum plate with four

properly

located holes and some hardware. I removed the levers from some spare

switches,

essentially converting the switches to push button operation, and

mounted

them on the upper links using the aluminum plates. The actuator is an

AN3 bolt,

some washers and a nut installed in an existing hole in the lower

link. This

configuration only shows green when the links are truly over center.

It

is very precise and makes the locked indication completely independent of

any

movement or rotation of the linkage relative to the airframe when the gear

is down. I

have not removed the original switches or wiring, but instead added

an

additional set of lights for testing this new set-up. The entire landing gear system, as designed, is

mechanically simple which helps make an actual system

failure a rare event. During my false indication

incidents,

I trusted the gear more than the indication, but I took the

opportunity

to buzz the control tower anyway.

Chris

Woodland